Instrumentasi adalah ilmu dari pengukuran otomatis(measurement) dan kontrol(control). Aplikasi dari Instrumentasi Industri ini sangat banyak dalam research modern, industri, dan kehidupan sehari-hari. Dari sistem kontrol automobil sampai ke termostat rumah hingga autopilot pesawat terbang hingga pembuatan obat farmasi, otomasi mengelilingi kita. Kali ini akan dijelaskan beberapa prinsip dasar instrumentasi industri.

Langkah pertama, tentu saja, adalah pengukuran. Jika kita tidak bisa mengukur sesuatu, sebenarnya tidak ada gunanya

cobalah untuk mengendalikannya Ini “sesuatu” biasanya mengambil salah satu dari bentuk berikut di industri:

• Tekanan cairan

• Aliran fluida

• Suhu suatu benda

• Volume cairan yang tersimpan dalam bejana

• Konsentrasi kimia

• Posisi mesin, gerak, atau akselerasi

• Dimensi fisik suatu benda

• Hitung (inventarisasi) objek

• Tegangan listrik, arus, atau hambatan

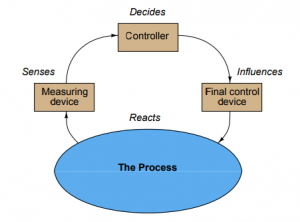

Begitu kita mengukur kuantitas yang kita minati/cari, biasanya kita mengirimkan sebuah sinyal yang mewakili kuantitas ini ke alat penunjuk atau komputasi dimana ada tindakan dari manusia atau benda yang bekerja scr otomatis pada saat itu terjadi. Jika tindakan yg diambil adalah pengendalian otomatis, komputer mengirimkan sinyal ke final controlling perangkat yang kemudian mempengaruhi kuantitas yang diukur.

Perangkat final control ini biasanya diambil dari salah satu dari bentuk berikut:

• Control Valve (Pengontrolan katup untuk mencekik laju alir fluida)

• Electric Motor (Motor listrik)

• Electric Heater (Pemanas listrik)

Baik perangkat pengukuran maupun perangkat Final Control terhubung ke beberapa sistem fisik yang

kita sebut “proses”. Untuk menunjukkan dari penggambaran proses tersebut dapat digambar dalam diagram blok umum:

Termostat rumah yang umum adalah contoh pada sistem pengukuran dan kontrol, dengan Suhu udara internal rumah menjadi “proses” yang akan dikendalikan. Dalam contoh ini, termostat biasanya menyediakan dua fungsi: penginderaan dan kontrol, sementara pemanas rumah menambahkan panas ke rumah untuk meningkatkan suhu, dan / atau pendingin udara di rumah mengeluarkan panas dari rumah untuk mengurangi suhu. Peran sistem kontrol ini adalah menjaga suhu udara pada beberapa kenyamanan yang dikehendaki, dengan pemanas atau AC mengambil tindakan kontrol untuk menyesuaikan suhu jika suhunya menyimpang terlalu jauh dari nilai yang diinginkan (disebut setpoint).

Sistem pengukuran dan pengendalian industri memiliki persyaratan dan standar unik tersendiri, yaitufokus utama pelajaran ini. Berikut adalah beberapa istilah instrumentasi dan definisi mereka yang umum:

Process: The physical system we are attempting to control or measure. Examples: water filtration system, molten metal casting system, steam boiler, oil refinery unit, power generation unit.

Process Variable, or PV: The specific quantity we are measuring in a process. Examples: pressure, level, temperature, flow, electrical conductivity, pH, position, speed, vibration.

Setpoint, or SP: The value at which we desire the process variable to be maintained at. In other

words, the “target” value for the process variable. Primary Sensing Element, or PSE: A device directly sensing the process variable and translating that sensed quantity into an analog representation (electrical voltage, current, resistance; mechanical force, motion, etc.). Examples: thermocouple, thermistor, bourdon tube, microphone, potentiometer, electrochemical cell, accelerometer.

Transducer: A device converting one standardized instrumentation signal into another

standardized instrumentation signal, and/or performing some sort of processing on that signal.

Often referred to as a converter and sometimes as a “relay.” Examples: I/P converter (converts 4-

20 mA electric signal into 3-15 PSI pneumatic signal), P/I converter (converts 3-15 PSI pneumatic

signal into 4-20 mA electric signal), square-root extractor (calculates the square root of the input

signal).

Note: in general science parlance, a “transducer” is any device converting one form of energy

into another, such as a microphone or a thermocouple. In industrial instrumentation, however, we

generally use “primary sensing element” to describe this concept and reserve the word “transducer”

to specifically refer to a conversion device for standardized instrumentation signals.

Transmitter: A device translating the signal produced by a primary sensing element (PSE) into

a standardized instrumentation signal such as 3-15 PSI air pressure, 4-20 mA DC electric current,

Fieldbus digital signal packet, etc., which may then be conveyed to an indicating device, a controlling

device, or both.

Lower- and Upper-range values, abbreviated LRV and URV, respectively: the values of process measurement deemed to be 0% and 100% of a transmitter’s calibrated range. For example, if a temperature transmitter is calibrated to measure a range of temperature starting at 300 degrees Celsius and ending at 500 degrees Celsius, its LRV would be 300 oC and its URV would be 500 oC.

Zero and Span: alternative descriptions to LRV and URV for the 0% and 100% points of an

instrument’s calibrated range. “Zero” refers to the beginning-point of an instrument’s range

(equivalent to LRV), while “span” refers to the width of its range (URV − LRV). For example,

if a temperature transmitter is calibrated to measure a range of temperature starting at 300 degrees

Celsius and ending at 500 degrees Celsius, its zero would be 300 oC and its span would be 200 oC.

Controller: A device receiving a process variable (PV) signal from a primary sensing element

(PSE) or transmitter, comparing that signal to the desired value (called the setpoint) for that

process variable, and calculating an appropriate output signal value to be sent to a final control

element (FCE) such as an electric motor or control valve.

Final Control Element, or FCE: A device receiving the signal output by a controller to directly

influence the process. Examples: variable-speed electric motor, control valve, electric heater.

Manipulated Variable, or MV: The quantity in a process we adjust or otherwise manipulate in

order to influence the process variable (PV). Also used to describe the output signal generated by

a controller; i.e. the signal commanding (“manipulating”) the final control element to influence the

process

Automatic mode: When the controller generates an output signal based on the relationship of

process variable (PV) to the setpoint (SP).

Manual mode: When the controller’s decision-making ability is bypassed to let a human operator

directly determine the output signal sent to the final control element.

diambil dari/taken from: Lessons In Industrial Instrumentation, version 2.23

0 Responses

Stay in touch with the conversation, subscribe to the RSS feed for comments on this post.